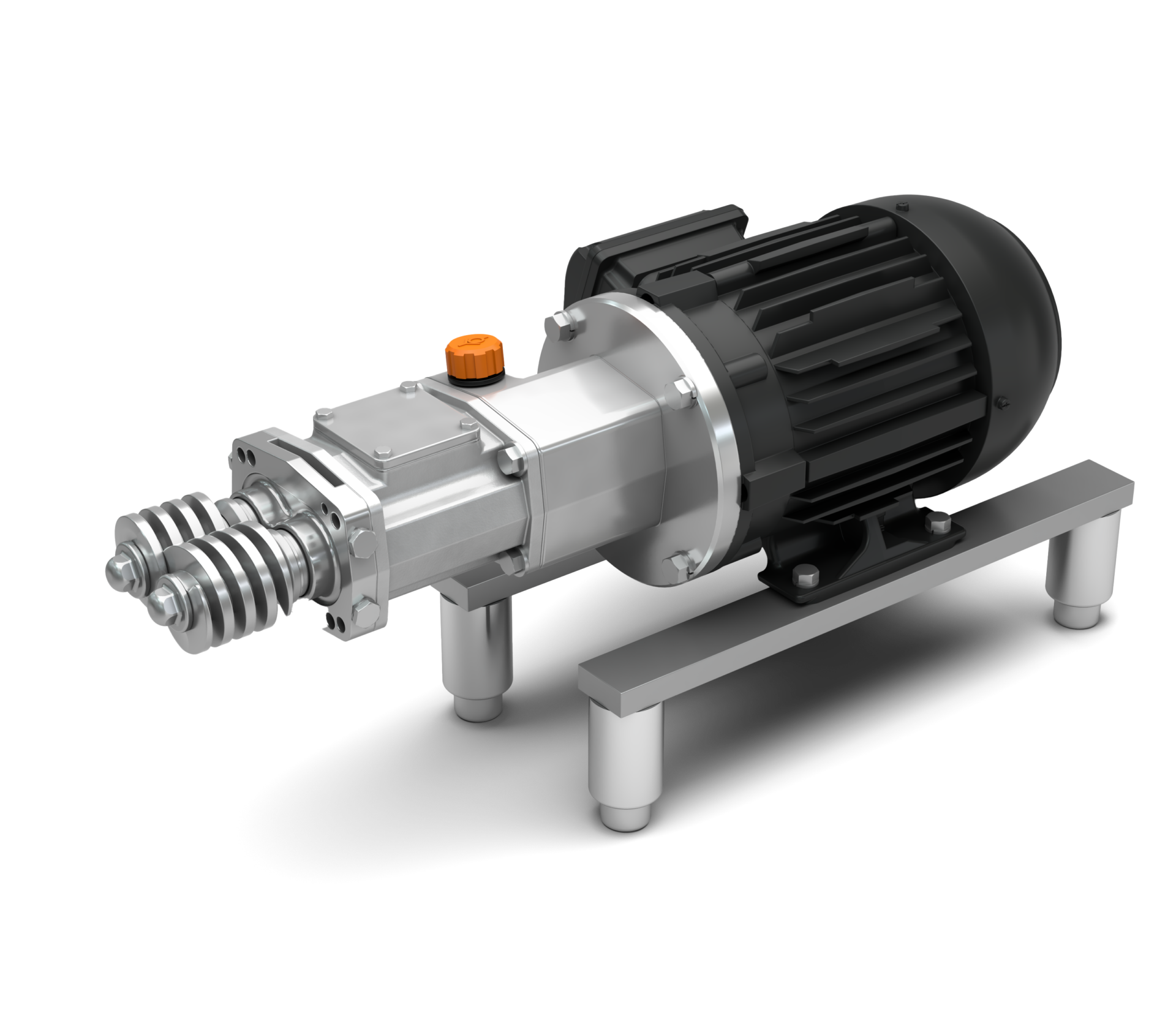

Introducing the World's Smallest Twin Screw Pump

Welcome to the future of fluid transfer technology with the New Fristam FDS Nano Twin Screw Pump. Designed for precision and efficiency, this innovative pump is perfect for a variety of applications across multiple industries including pharmaceutical, dairy, food and personal care. Explore how the FDS Nano can revolutionize your operations.

What is the FDS Nano Twin Screw Pump?

The Fristam FDS Nano Twin Screw Pump is a cutting-edge pump designed for the gentle and efficient transfer of delicate fluids. Utilizing twin screw technology, it offers a unique blend of high performance and low shear, making it ideal for applications that require careful handling of sensitive materials.

Key Applications

The FDS Nano is extremely versatile and can be used across a wide application spectrum, including:

- Pharmaceutical: Ideal for handling shear-sensitive fluids like blood, immunoglobulins, antibodies and proteins while maintaining sterility throughout the process.

- Food, Dairy & Beverage: Perfect for transferring liquids with variegates like fruit purees, yogurt, sauces, and dairy products without damaging the integrity of the product.

- Cosmetics: Efficiently moves high-viscosity creams and lotions with precision.

- Chemical Processing: Handles a range of chemicals, polymers and emulsions, providing reliable performance in demanding environments.

- CIP fluids: Eliminating the need for extra pumps in your system.

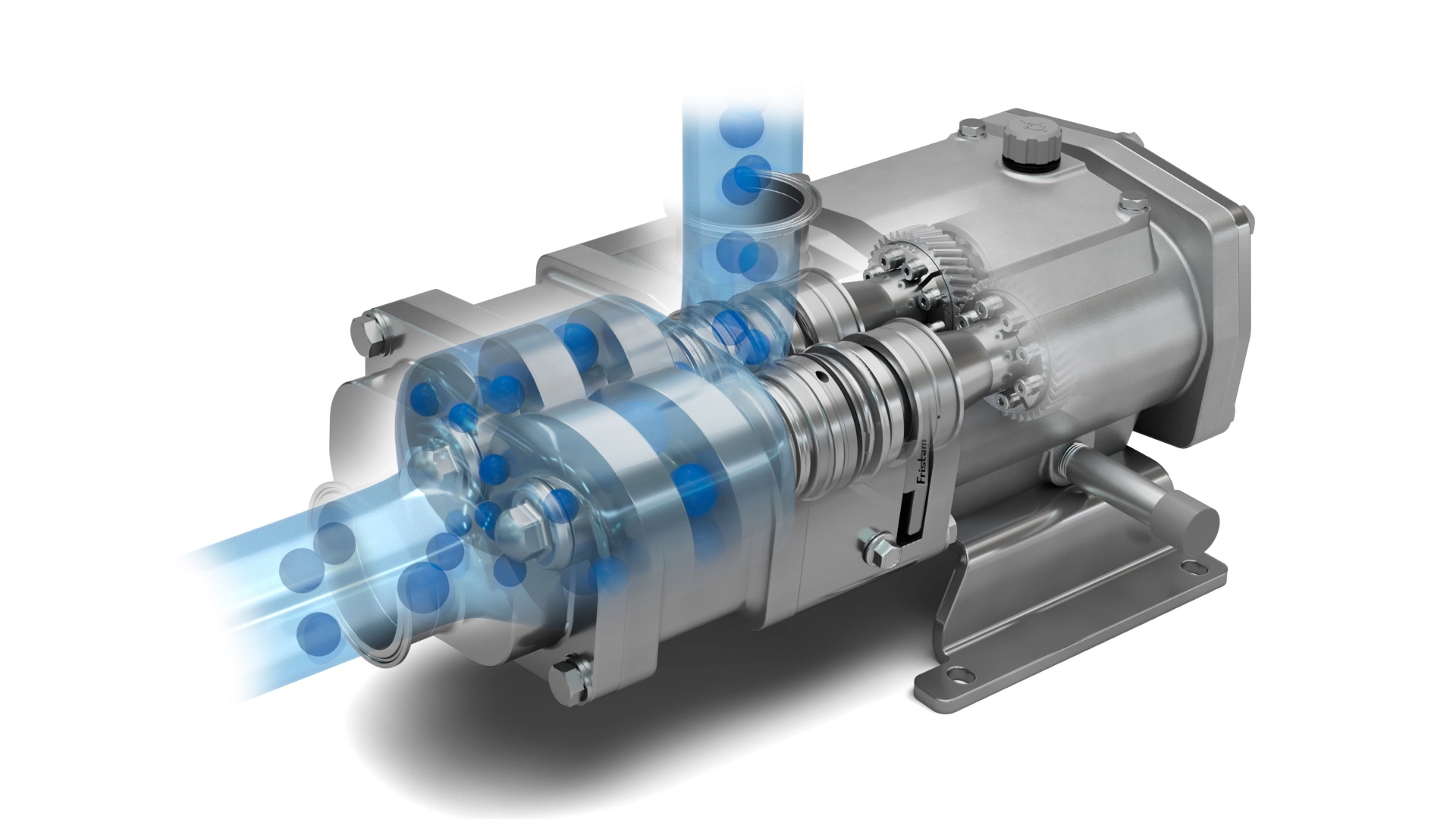

How It Works

The FDS Nano operates using a twin screw mechanism that creates a continuous flow of fluid. The two inter-meshing screws rotate within a cylindrical housing, drawing in liquid from the inlet and delivering it at a consistent flow rate. This design minimizes turbulence and shear, making it particularly suitable for sensitive materials.

Key operational benefits include:

- Low Shear: Preserves the integrity of the fluid being pumped.

- Self-Priming: Can handle variations in viscosity without losing efficiency.

- Gentle Handling: Ideal for delicate and high-value products.

- Multi-Purpose Pump: Can be used to pump both process & CIP fluids, eliminating the need for an extra pump

Features & Benefits

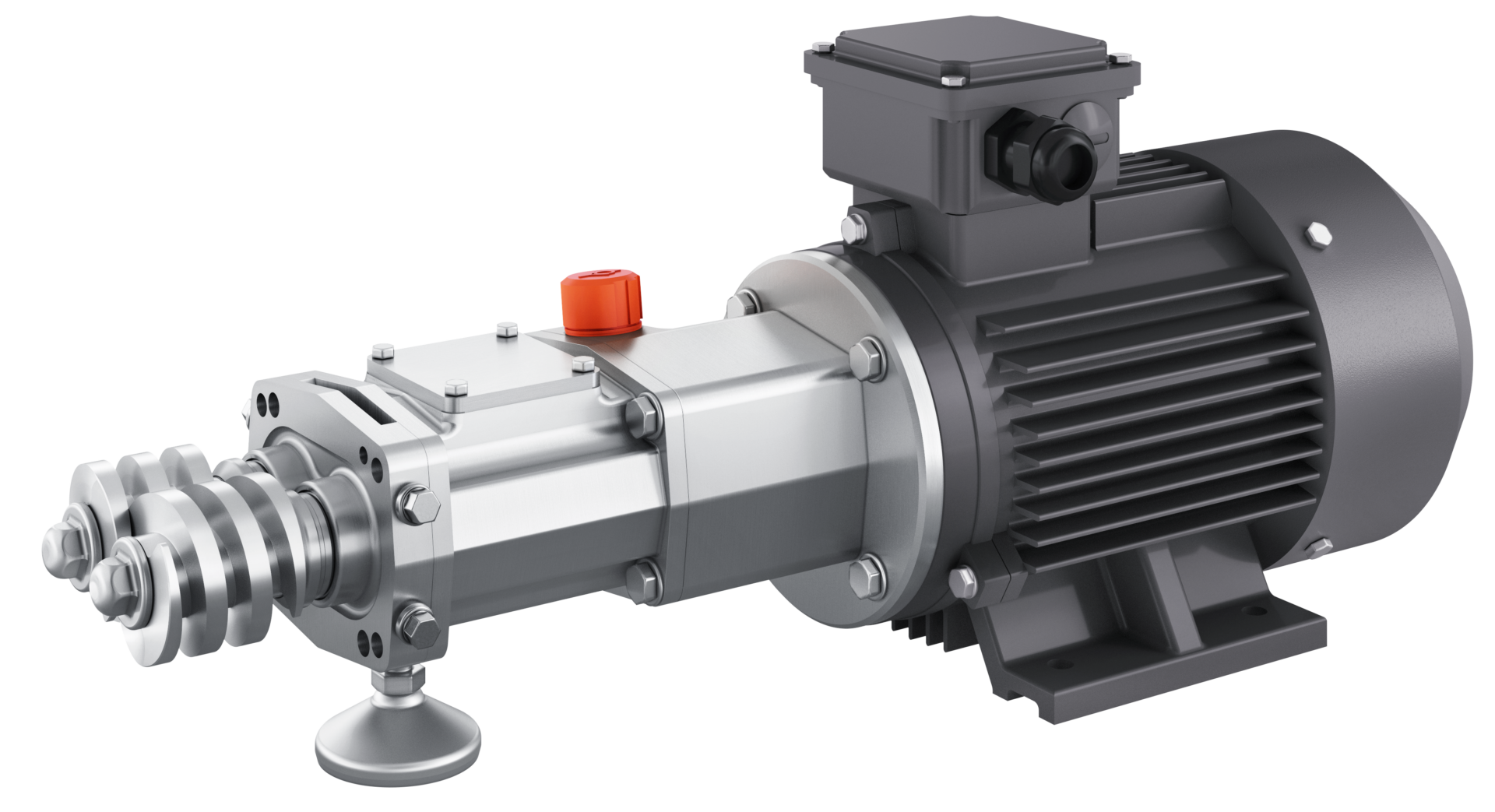

Features:

- Contact-Free Screws: Ensures smooth, continuous flow with low pulsation. Available in six standard sizes to optimize efficiency based on specific application requirements.

- Versatile Speed Control: Adjustable to meet continuous or metered flow requirements.

- Compact Size: Easy to install in tight spaces, reducing the footprint in your facility.

- Easy Maintenance: Designed for quick disassembly and cleaning, ensuring compliance with hygienic standards.

- Front Loading Seals: Designed for easier maintenance, minimizing downtime.

- Flexible Coupling: Effectively eliminates vibration between the pump and driver, enhancing overall performance.

Benefits:

- Enhanced Product Quality: Maintains the integrity of shear-sensitive materials, resulting in higher quality outputs.

- Increased Efficiency: Optimizes flow rates and reduces downtime with reliable performance.

- Cost-Effective: Low operational costs due to energy-efficient design and minimal maintenance requirements.

Options:

- Direct drives or geared motors (depending on duty)

- C-Face Motor (56C or 143TC)

- Multiple screw pitches available based on application requirements

- Baseplate / Adjustable legs / Motor shroud as options

- Heated Pump casing

Designed with you in mind!

The FDS Nano Twin Screw Pump is an excellent choice for applications requiring precise, reliable, and efficient fluid transfer. Its unique design ensures smooth and consistent flow, making it ideal for handling sensitive liquids, including those with varying viscosities or particulates. The pump’s twin screw mechanism minimizes pulsation, reduces shear, and maintains high efficiency even at low flow rates. Its compact size makes it suitable for tight spaces, while its robust construction ensures durability and long service life. Overall, the FDS Nano Twin Screw Pump offers superior performance, versatility, and ease of maintenance, making it a top choice for industries like food processing, dairy and pharmaceuticals.

For more information, contact Fristam or an authorize distributor today!

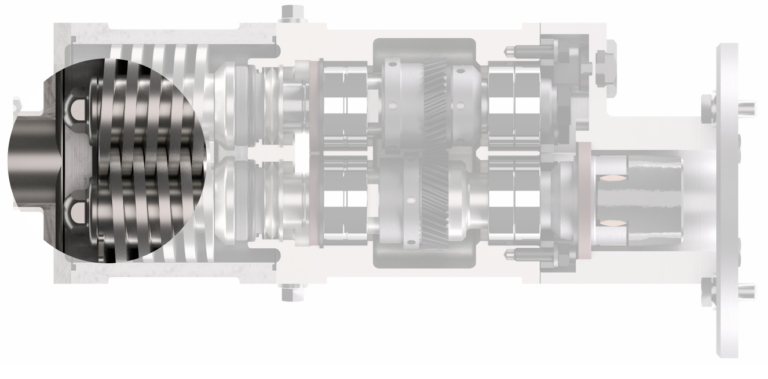

Tight Clearances

Less backflow

Highest possible efficiency

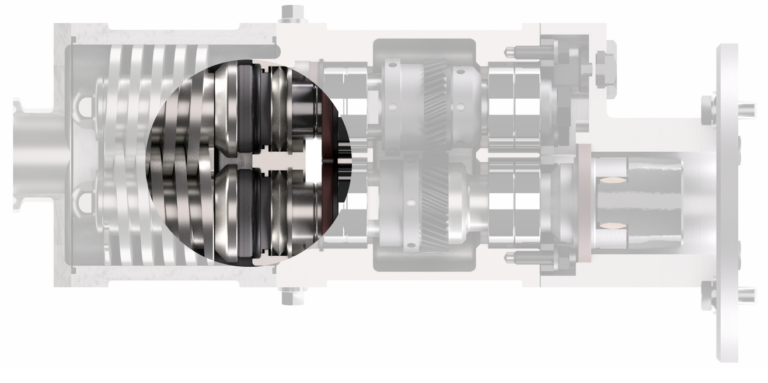

Mechanical Seals

Integrated into seal housing

Ensures longest possible lifespan

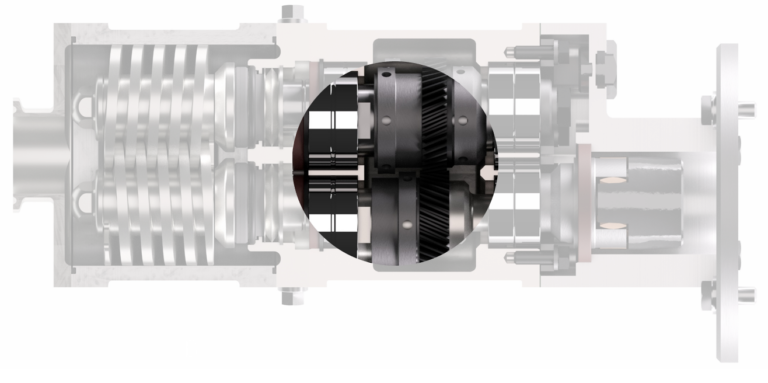

Screw Alignment

Reachable without removing pump or motor from the line

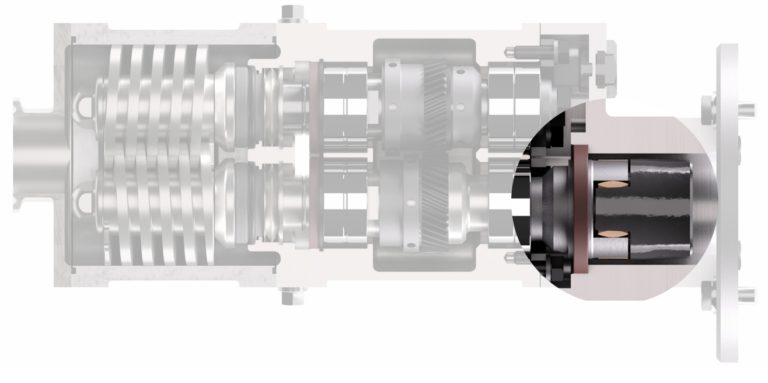

Flexible Couplings

Located outside the oil bath

Driven by various drivers

NEW:

FDS Nano Model Specifications

| Model | Max. discharge pressure [bar (PSI)] | Maximum flow rate [m3/h (gpm)] | Max. rotation speed [RPM] | Connection [mm (in)] | Max Viscosity | Rotation | Temperatures | Mounting | Mechanical seals | Feed screws | Max. particle size [mm (in)] | Options |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nano | 10 (145) | Product: 0.5 (2.2) CIP: 3 (13) | 4,000 | 10-40 (.5-1.5) | 1,000,000 cps | Reversible | Up to 150°C (302°F) standard 220°C (428°F) optional | Horizontal (standard) Vertical and sideways optional | Single or single flushed | 6 | 12 (.5) | Heated jacket, special surface treatments, electropolishing, custom adaptations to specific products, processes and systems |